ACTIVATED CARBON AND ACTIVATED CARBON PLANTS RELATED SERVICES

As you surely know, vegetal activated carbon is since far along disappeared from the market, and the actual activated carbon present on the market is all from mineral origin.

Old Customers of vegetal carbon well know the advantages of this carbon, that was the best medium for solvent recovery and gas purification, advantages reassumed as follows:

LOWER DENSITY OR A LOWER WEIGHT

IN A SPECIFIC VOLUME:

VERY HIGH ATTRITION RESISTANCE:

HIGHER THERMAL SHOCK RESISTANCE:

this means less disgregation in particles and longer carbon life.

GREATER ACTIVATED SURFACE:

ISOTHERM EQUILIBRIUM OF 46

% OF BENZENE ADSORPTION AT 0,9 p/p1 AND 32% AT 0,01:

MORE RETENTIVITY AND LESS STEAM

CONSUMPTION:

LESS ACIDIFICATION POWER, LESS

HYDROLYSIS - BOTH FOR STEAM AND HOT GAS - AND LOWER BYPRODUCTS (LIKE ACID)

FORMATION DURING THE REGENERATION:

this means 3 time less acid formation and high boiling byproducts.

CERTIFIED ASH AND HUMIDITY:

for vegetal carbon no dust or water is sold at carbon's price.

The

vegetal carbon was mainly produced in Europe by the German Degussa. After

having bought Degussa, the American Chemviron has shut down the production

facility in Germany and the vegetal carbon more or less has disappeared

from the market, enforcing Customers to buy far-east produced activated

carbon of mineral origin.

The

vegetal carbon was mainly produced in Europe by the German Degussa. After

having bought Degussa, the American Chemviron has shut down the production

facility in Germany and the vegetal carbon more or less has disappeared

from the market, enforcing Customers to buy far-east produced activated

carbon of mineral origin.

Omniatex is glad to inform you that a newest facility

for the production of vegetal activated carbon, with Degussa experience

and know-how, has entered production in Germany and our Society is the

only one distributor in Italy of the new vegetal highly activated carbon,

with also the possibility to sell the carbon in other Countries.

Omniatex is glad to inform you that a newest facility

for the production of vegetal activated carbon, with Degussa experience

and know-how, has entered production in Germany and our Society is the

only one distributor in Italy of the new vegetal highly activated carbon,

with also the possibility to sell the carbon in other Countries.

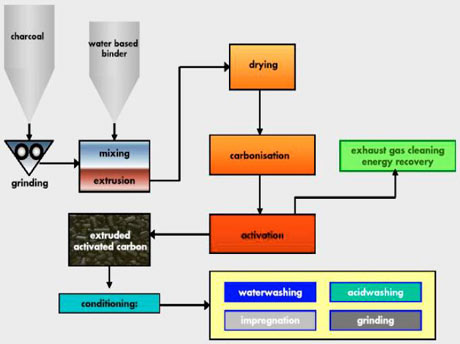

The vegetal activated carbon is produced with a row material that is strictly controlled and with a quality resulting in an highly activated carbon, with the use of a natural binding agent, of natural origin, extremely resistant to the water.

See the production cycle of the vegetal carbon in the following block diagram:

|

|

|

|

| Adsorption/Desorption test | Thermogravimetric test |

|

With this new opportunity Omniatex can also supply

any kind of service required by any activated carbon recovery plant, as:

|

|

|

|

|

|

|

Packaging of old carbon in big bags

|

Shivering of old carbon

All these services are offered in all continental Europe and all the jobs are performed according to German norm DIN 3188 and specifications BG: ZH1/77 et ZH1/78 with full respect of any Safety regulation.

The jobs are carried out with proprietary tools, equipment and machinery and the Customer has not to provide fans, air compressor, vacuum units, filters, cranes, fork lifts or any other kind of tools that is required by the job and in full respect of the Environment.

© Omniatex srl