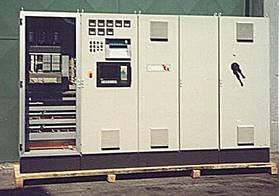

electrical panels for power supply

and process control

| The

Company has always been working, since the beginning, in the manufacturing of

electrical panel and automatic control systems field with its own internal department. The proprietary know how, acquired and developed since

more than 30 years, allows the study and manufacturing of electrical panel and

automatic control systems for every kind of industrial processes. |

|  |

Special control processes have been applied to fans and pumps control,

even in parallel, with asthonishing results for what is concerning the energy

savings with pay-back obtained in very short time.

|

|

|

|

Special design and special manufacturing solutions have allowed the realization,

after years of ban, of the first solvent storage farm approved by both the

local and regional Fire Fighting Dept for construction “above ground” and not

“underground” like usually required. The solvent distribution to all the several

services of the shop is finely controlled in real time with the recording of

all data concerning density and temperature correction of the solvent for a

global and reliable global moving record.

Special control systems have been applied for the distribution of inks

and paints, for multi-distillation plants, for chemical treatment of solvents,

for treatment of aqueous solutions and for the control of reactors, evaporators

and mixers.

All the realized software is foreseen for the transmission of data, of

the most important variables, to a control room far away from the plant itself,

like boiler’s rooms and Engineering Offices that can be qualified for remote

action on the plant.

Several plants have been

interconnected to other plants, to production machines and also production

nachines have been interconnected to other production lines. All control panels

and control systems are conforming to DIN, CEI, ATEX, APAVE, SA, GOST Rules,

and delivered with “CE” stamp with EN 60204-1 Par.2, CEE 93/465, 73/23, 89/392

certification.

The study and

developing fo the software produced all internally make the Company free from

any external Softer house and make the answering to any Customers requirements

very easy in few hours.